Corrugated aluminum cladding roll used for insulation are a lightweight, high-strength, corrosion-resistant building material that is widely used in industrial and civil buildings, pipeline insulation, cold storage, air conditioning systems and other fields. Corrugated aluminum cladding use a special corrugated structure to form an air channel between the panel and the back panel, which plays a role in heat insulation. Under solar radiation, the air in the channel heats up and flows upward to take away the heat, achieving heat insulation; in cold areas, the upper and lower ends of the corrugated channel are sealed, and heat energy can be stored under sunlight during the day to reduce the loss of indoor heating heat.

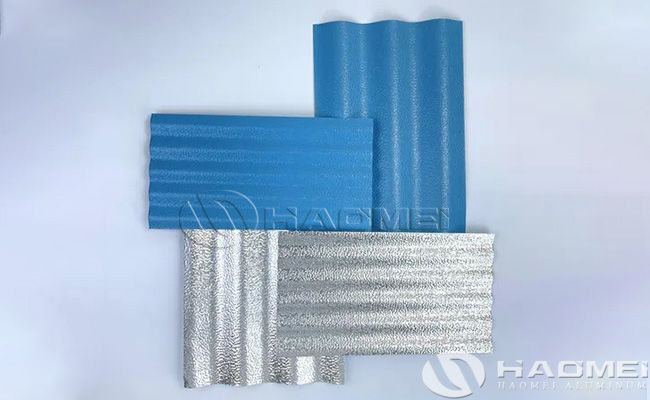

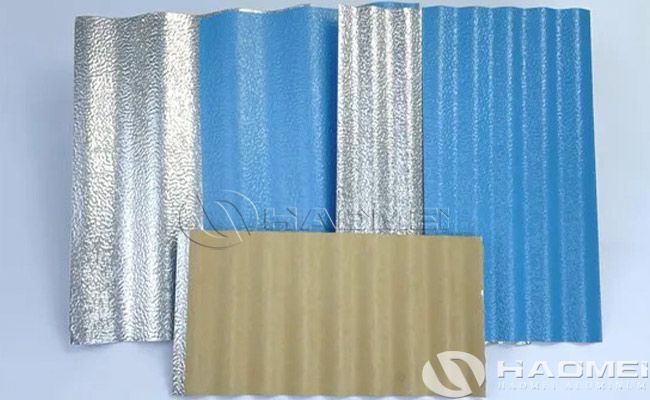

Material selection of corrugated aluminum cladding roll:

- 1060 pure aluminum:

Has good corrosion resistance, formability and weldability, and is relatively low in price. It is suitable for general insulation occasions with low strength requirements, such as insulation of building walls and roofs, and insulation of some ordinary pipes.

- 3003 aluminum alloy:

Manganese is added to pure aluminum to improve the strength and corrosion resistance of the material, while maintaining good processing performance. It is one of the commonly used materials for thermal insulation corrugated aluminum cladding sheet and can be used for thermal insulation projects with high requirements for corrosion resistance and strength, such as pipeline insulation in chemical plants and refineries.

- 3004 aluminum alloy:

It is an aluminum-manganese-magnesium alloy with higher strength and corrosion resistance, especially in terms of fatigue resistance and deformation resistance. It is often used for thermal insulation of building roofs and walls with high requirements, as well as thermal insulation protection of some large tanks and containers.

Common specifications of corrugated aluminum cladding:

- Thickness: Generally between 0.2-1.5mm, common ones are 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm etc. Different thicknesses are suitable for different thermal insulation requirements and usage scenarios.

- Width: Usually 600-1500mm, which can be customized according to actual needs.

Insulation principle of corrugated aluminum cladding:

- Air insulation:

The air channel formed by the corrugated core of the corrugated aluminum roll is an important factor in its insulation. Air is a poor conductor of heat, which can effectively prevent the transfer of heat and reduce the exchange of heat between indoor and outdoor.

- Heat reflection:

Aluminum itself has a high reflectivity, which can reflect part of the solar radiation heat, reduce heat absorption, thereby reducing the surface temperature of the object and playing a role in insulation.

- Insulation material assistance:

Some corrugated aluminum cladding will be filled with insulation materials such as polyurethane foam during the production process to further enhance the insulation effect.

Features of corrugated aluminum cladding:

- Light weight:

The density of aluminum is only one-third of that of steel. Using corrugated aluminum jacketing for insulation can greatly reduce the overall weight of the building while ensuring the insulation effect, which is convenient for construction and transportation, and also reduces the load-bearing requirements for the building structure.

- Convenient and fast construction:

Corrugated aluminum cladding can be rolled and cold-bent into various corrugated profiled plates as needed. They are easy to process and shape, and can adapt to insulation objects of different shapes and sizes. They can greatly shorten the construction period and reduce the construction intensity.

- Beautiful and durable:

It has a metallic texture, bright and neat appearance, strong decorative effect, and can add beauty to the building. At the same time, aluminum has good corrosion resistance and oxidation resistance, is not easy to rust and corrode, has a long service life, and can generally be used for more than 20 years in natural environment, and has low maintenance cost.

- High recycling value:

Compared with traditional insulation materials such as iron sheets, corrugated aluminum cladding have a high recycling rate after use, at least 80% can be recycled, and have high economic value.

Application field of corrugated aluminum cladding roll:

- Construction field:

It is widely used in industrial and civil buildings, warehouses, special buildings, roofs, walls, and interior and exterior wall decorations of large-span steel structure houses, etc., which can effectively improve the insulation performance of buildings and reduce energy consumption.

- Pipeline insulation:

It is suitable for pipeline insulation projects of various factories such as power plants, chemical plants, refineries, pharmaceutical plants, etc. It can prevent the heat loss of the medium in the pipeline, reduce energy loss, and protect the pipeline from corrosion from the external environment.

- Other fields:

It can also be used for packaging of some equipment and tanks that require thermal insulation, such as wine tanks, storage tanks, etc. It helps to keep the temperature of the internal items stable and improve product quality and storage period.

live:onlinehcx