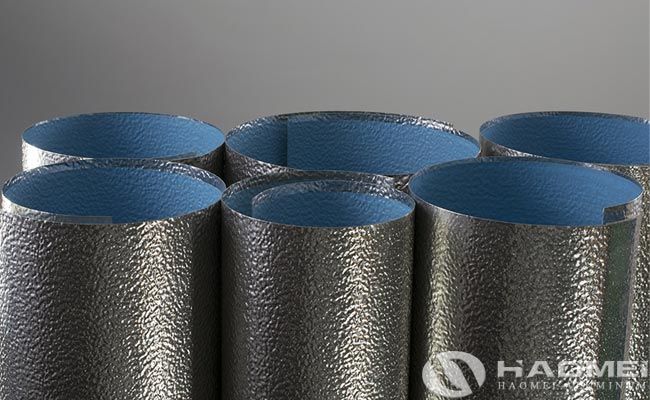

Stucco embossed aluminum jacketing with Surlyn polymers combine the superior properties of Surlyn material with the structural advantages of stucco embossed aluminum coils, resulting in outstanding performance in insulation, protection, aesthetics and durability.

Basic composition of stucco embossed aluminum jacketing with surlyn polymers:

- Aluminum substrate:

Typically made of materials such as 1060 pure aluminum or 3003 aluminum-manganese alloy, it features lightweight, strong corrosion resistance, and good plasticity. Common thicknesses range from 0.3-1.2 mm.

- Surlyn Polymer film:

Surlyn resin is an ethylene-methacrylic acid copolymer produced by Dow Chemical (formerly DuPont), which is partially or completely neutralized. It possesses excellent abrasion resistance, scratch resistance, and chemical resistance, and can be directly heat-bonded to metal surfaces.

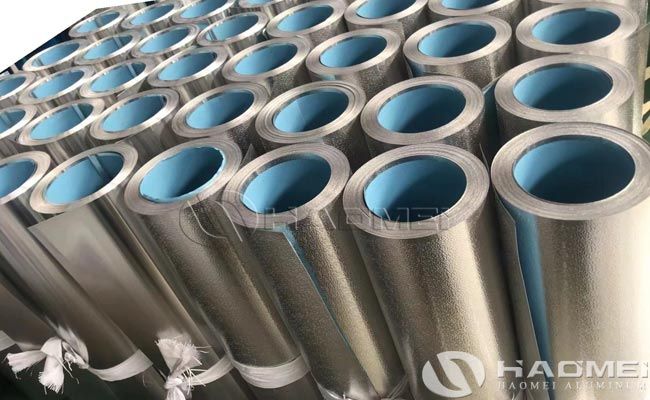

- Production process:

First, the aluminum material is automatically trimmed. Then, a Surlyn polymer film is placed on the surface of the bare aluminum roll jacketing. It is then hot-pressed at a specific temperature, followed by embossing, online shaping, cooling, automatic cutting, shearing, and packaging to create an stucco embossed aluminum jacketing with polysurlyn moisture barrier.

Core characteristics of Surlyn polymer:

1. Physical properties:

Impact resistance and flexibility: As an ethylene-methacrylic acid copolymer, Surlyn exhibits excellent low-temperature impact resistance, resisting cracking even under external impact while maintaining flexibility to adapt to complex installation environments.

Abrasion and scratch resistance: High surface hardness effectively resists scratches during transportation and installation, extending service life.

Sealing and weather resistance: Excellent low-temperature sealing performance, wide sealing temperature range, and resistance to UV radiation and aging, suitable for long-term outdoor use.

2. Chemical stability:

Oil/Grease resistance: Inert to various chemicals, especially suitable for environments involving grease and solvents, such as food packaging and chemical pipeline insulation.

Corrosion resistance: When combined with aluminum jacketing rolls, it further enhances the corrosion resistance of aluminum, making it suitable for humid or corrosive gas environments.

3. Optical and surface properties:

High transparency and gloss: The high transparency of the Surlyn film maintains the surface gloss of the aluminum coil, enhancing the product's aesthetics.

Processability: It can be laminated with aluminum coils through processes such as co-extrusion and casting to form a uniform and dense protective layer.

Structural advantages of stucco embossed aluminum jacketing:

1. Functionality of embossed design:

Enhanced friction: Surface embossing (such as orange peel texture) increases the coefficient of friction, preventing slippage and facilitating installation and fixation.

Increased strength: The embossing process can locally increase the rigidity of the aluminum jacketing, improving its resistance to deformation.

Aesthetic decoration: The textured design gives the aluminum jacketing a three-dimensional feel, suitable for scenarios with high aesthetic requirements (such as building exteriors and interior decoration).

2. Optimized insulation performance:

Enhanced heat reflection: The embossed surface increases the heat radiation reflection area, reducing heat loss and improving insulation efficiency.

Composite structure: After aluminum jacketing are combined with Surlyn membranes, further insulation materials (such as polyurethane and rock wool) can be added to form a multi-layer insulation system.

Applications of stucco embossed aluminum jacketing with surlyn polymers:

1. Construction Sector

Exterior wall insulation and decoration: Surlyn membranes protect aluminum jacketing from wind and rain erosion, while embossed designs enhance the building facade's texture and meet energy-saving requirements.

Roof waterproofing: The corrosion resistance of aluminum jacketing combined with the sealing properties of Surlyn membranes makes it suitable for waterproofing layers on metal roofs.

2. Industrial Pipelines and Equipment

Pipeline insulation: In the petroleum and chemical industries, Surlyn's oil resistance prevents corrosion of the pipe's outer layer due to grease penetration, while embossed aluminum jacketing provide mechanical protection.

Equipment protection: Used for high-temperature equipment such as boilers and steam pipes, Surlyn's weather resistance ensures long-term stable operation.

3. Cold chain and food packaging

Refrigerated trucks/Cold storage: Surlyn's low-temperature sealing prevents cold air leakage, while the low thermal conductivity of aluminum jacketing reduces energy consumption.

Food containers: Surlyn complies with FDA standards and can directly contact food, while stucco embossed aluminum jacketing provide structural support.

live:onlinehcx