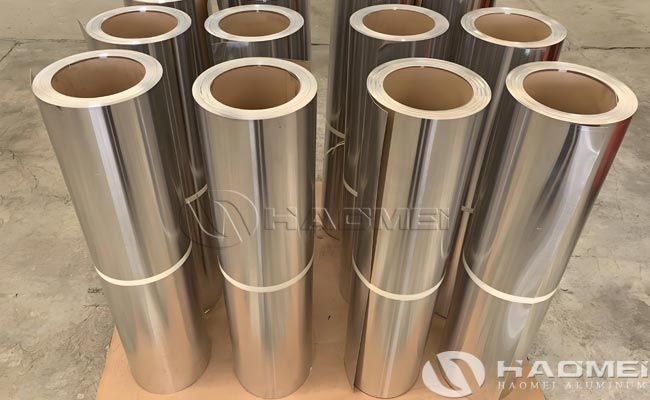

As a supplier specializing in the export of aluminum jacketing for many years, we consistently focus on the core needs of overseas customers, creating insulation aluminum jacketing coil with kraft paper back suitable for various industrial and residential pipeline insulation scenarios worldwide. With high-specification quality, user-friendly structure, and outstanding application advantages, we have become the preferred partner for pipeline insulation projects of many overseas companies. Below, we provide a detailed analysis of this best-selling export product from its core dimensions.

Regarding alloy specifications, we adopt export-standard customized production. Our main alloy models are 1060 and 3003, while we can also customize special specifications such as 1100 and 5052 according to customer needs, fully adapting to the pipeline insulation standards and operating conditions of different countries and regions. The 1060 pure aluminum alloy boasts high purity and excellent ductility, with customizable thicknesses from 0.3-3.0mm and widths from 800-1900mm, suitable for conventional medium- and low-temperature pipeline insulation. The 3003 aluminum-manganese alloy, reinforced with manganese, offers higher strength than the 1060 series and superior corrosion resistance, making it suitable for pipelines in high-humidity and moderately corrosive environments. Both main models undergo bending and straightening treatment, resulting in excellent flatness and no wavy deformation, facilitating subsequent cutting and wrapping. All alloy materials meet international export environmental and quality standards, and complete material testing reports are available to ensure smooth customs clearance.

The product structure employs a layered composite design, balancing insulation, protection, and ease of construction. The core consists of three layers: a custom-designed aluminum jacketing coil substrate on the surface, a high-adhesion environmentally friendly composite adhesive layer in the middle, and an imported premium kraft paper backing (80-200g/m² optional). The adhesive layer uses environmentally friendly polyurethane adhesive, offering high bonding strength, resistance to delamination, and the ability to withstand extreme temperature differences from -40℃ to 85℃. The kraft paper backing undergoes special moisture-proof treatment, resulting in a tough and tear-resistant texture that adheres tightly to the aluminum coil substrate, forming a double barrier of "aluminum coil protection + kraft paper moisture protection." This also prevents scratches on the aluminum coil surface during construction, protecting the product's appearance. The overall roll packaging design allows for 50-meter small rolls (suitable for small-scale pipeline construction) or 2.7-3 ton large rolls (suitable for large-scale projects). Export-grade wooden and iron pallets are used for packaging, effectively preventing moisture and damage during transportation.

Its core advantages are prominent, adaptable to various export scenarios:

First, it offers dual high efficiency in thermal insulation and moisture-proofing. The aluminum coil surface has a reflectivity of up to 97%, effectively blocking heat conduction and UV radiation. The kraft paper backing absorbs moisture inside the pipe and isolates external water vapor intrusion, preventing the insulation layer from aging due to moisture and extending the pipe's service life.

Second, the material is lightweight yet strong. Compared to traditional protective materials, it is lighter and easier to transport, reducing overseas construction labor costs. It also possesses excellent impact and tensile strength, adaptable to pipeline laying in various terrains.

Third, it is environmentally friendly and efficient to install. It contains no harmful volatile substances, meeting environmental standards in the EU, North America, and other regions. The backing is self-adhesive, allowing direct application to the insulation layer without additional adhesive, significantly improving construction efficiency.

Fourth, it is corrosion-resistant and widely adaptable, suitable for various complex working conditions such as marine climates and corrosive industrial environments. It is not prone to rusting or delamination, and its application scope covers various industrial and domestic pipelines.

In pipeline insulation applications, the advantages of aluminum jacketing with polykraft paper are particularly significant, making it the preferred solution for overseas pipeline insulation projects.

Firstly, it adapts to various pipe shapes, whether straight, curved, or irregularly shaped. Its excellent ductility allows for flexible cutting and tight wrapping, ensuring a seamless and secure fit, preventing heat loss and moisture infiltration.

Secondly, it effectively extends the lifespan of pipe insulation systems, preventing corrosion, condensation, and freezing due to temperature differences and moisture. It is particularly suitable for outdoor pipes in the petroleum, chemical, power, and residential water and heating industries, performing exceptionally well in highly corrosive environments such as oil refineries and nuclear power plants.

Thirdly, it reduces maintenance costs. The product is highly weather-resistant, resistant to aging and damage over long-term use, eliminating the need for frequent replacements. The kraft paper backing effectively protects the aluminum coil surface, reducing losses during construction and use.

Fourthly, it meets the needs of large-scale overseas engineering projects. Standardized production and bulk supply allow for customized specifications based on customer orders. The convenient roll packaging design significantly improves construction efficiency and shortens project cycles. Furthermore, comprehensive export services include customs clearance documentation and full logistics tracking to ensure timely delivery.

We consistently prioritize export quality, rigorously controlling every stage of production, from alloy selection and composite processing to packaging and transportation, adhering to international standards throughout. We also provide customized services and comprehensive after-sales support to help overseas clients reduce construction costs and improve project quality. For inquiries regarding specific alloy specifications, bulk pricing, or export-related matters, please feel free to contact us to collaborate and achieve mutual success in the overseas pipeline insulation market.

live:onlinehcx