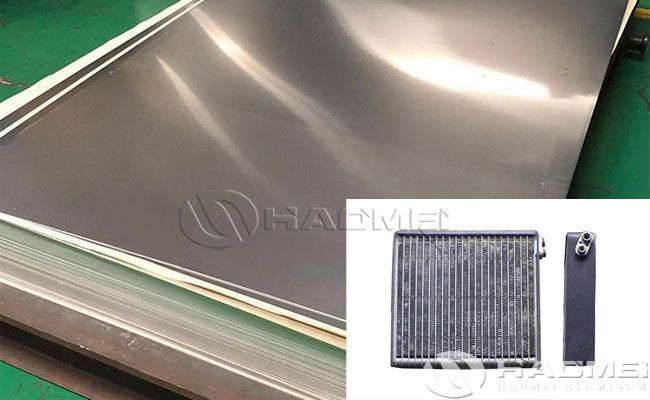

4045/3003/4045 aluminum brazing sheets, with their unique structural design and superior performance, have been widely used in new energy vehicles, energy storage equipment, and high-end electronic heat dissipation, especially in environments requiring high strength and good corrosion resistance.

Structurally, the 4045/3003/4045 aluminum brazing plate consists of three layers of aluminum alloy: an outer layer of 4045 aluminum alloy, a middle layer of 3003 aluminum alloy, and a third outer layer of 4045 aluminum alloy. This three-layer structure not only improves welding performance but also enhances the overall strength of the material.

The surface layer of 4045 aluminum alloy has a silicon content as high as 10%-13%, and its melting point is more than 20°C lower than that of pure aluminum. During brazing, it melts first to form a liquid metal bridge, filling the micron-level gap between the core material and the base material through capillary action. This allows for the formation of high-quality welds and reduces the risk of oxidation during welding. This self-wetting property results in a porosity of less than 0.05% in the brazed joint, far exceeding that of traditional soft brazing processes.

The intermediate layer, made of 3003 aluminum alloy, serves as the main structural component, with its manganese content precisely controlled within the range of 1.0%-1.5%. This compositional design endows the material with a unique "memory effect"—its yield strength fluctuates by no more than 15% within a temperature range of -50℃ to 150℃, ensuring that the water-cooled plate maintains the geometric accuracy of the flow channels even under extreme conditions. More importantly, the 3003 matrix and 4045 brazing filler metal form a eutectic structure at a high temperature of 600℃, achieving an interfacial bonding strength of up to 180MPa, equivalent to 92% of the base material strength.

In terms of advantages, the 4045/3003/4045 aluminum brazing sheet exhibits multiple benefits. First, its excellent weldability enables high-strength connections at relatively low temperatures, saving energy consumption. During the welding process, the strength and toughness of the weld joint are effectively guaranteed due to the characteristics of the 4045 aluminum alloy. Furthermore, this aluminum brazing sheet has excellent corrosion resistance, making it particularly suitable for use in humid or chemically corrosive environments. Therefore, many industries consider the durability and reliability of this type of aluminum brazing sheet when selecting materials.

In application areas, 4045/3003/4045 aluminium brazing sheets have a wide range of applicability. In automotive manufacturing, lightweighting is an important means of improving fuel efficiency, and the high strength and low density of this type of aluminum brazing sheet perfectly meet this requirement. Many automakers have begun to use it in body structures and radiators to improve the overall performance and safety of vehicles. In the aerospace field, due to the stringent requirements for material strength and weight, 4045/3003/4045 aluminum brazing sheets, with their excellent properties, have become an ideal choice for aircraft structural components and assemblies. Furthermore, this type of aluminum brazing sheet is also widely used in the heat dissipation systems of electronic products to ensure temperature control of electronic components, improving product reliability and lifespan.

Market feedback shows that customers have a high level of satisfaction with 4045/3003/4045 aluminum brazing sheets, especially in terms of welding performance and corrosion resistance. Many users have stated that its performance in practical applications exceeds expectations. Market research indicates that products using this type of clad aluminum brazing plate outperform those using traditional materials in terms of durability and maintenance costs. This not only enhances product competitiveness but also creates greater economic benefits for customers.

As a professional 4045/3003/4045 aluminium brazing sheets manufacturer, we possess core technologies covering the entire process from casting to finishing. Utilizing German SMS rolling mills and online annealing technology, we can achieve customized production with a maximum width of 2650mm and a thickness of 0.2-3.0mm. Our unique three-layer composite rolling process controls the cladding thickness deviation within ±0.02mm, ensuring consistent brazing performance for each plate. For customers requiring high strength, corrosion resistance, and excellent weldability, this is undoubtedly an ideal choice.

live:onlinehcx