Chilled water pipe aluminium jacketing is a material used for pipe insulation, primarily in construction, air conditioning, refrigeration and industrial piping systems. Its primary function is to reduce heat loss, prevent condensation, and protect pipes from environmental influences.

1060 and 3003 are two different alloy grades of chilled water pipe aluminum jacketing with distinct properties.

- 1060 aluminum alloy: This is pure aluminum with an aluminum content of at least 99.6%. It offers excellent corrosion resistance and thermal conductivity, making it suitable for applications requiring excellent thermal conductivity and oxidation resistance. 1060 aluminum jacketing is typically used in applications requiring lightweight material and good processability.

- 3003 aluminum alloy: This is an aluminum-manganese alloy with high strength, good formability, and excellent corrosion resistance. 3003 aluminum alloy boasts higher strength than 1060 aluminum alloy and is suitable for applications subject to mechanical stress. It is often used in insulation casings.

Specifications of chilled water pipe aluminium jacketing roll:

- Thickness: Generally ranges from 0.1-3mm, with a commonly used thickness of 0.3-1.2mm for chilled water pipe insulation.

- Width: Typically ranges from 100mm to 1500mm, customizable upon request.

- Inner Diameter: Common options include Φ75mm, 150mm, 300mm, 400mm, and 500mm.

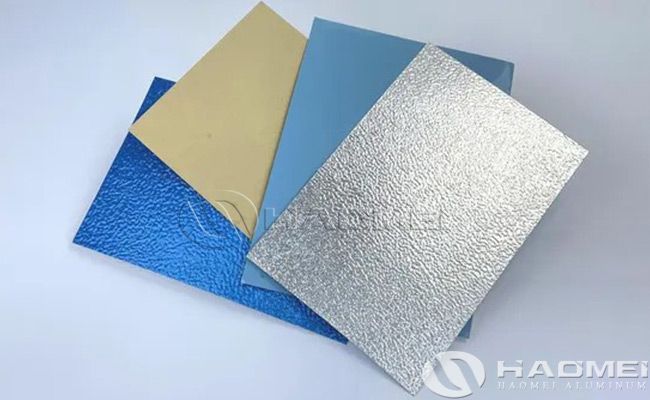

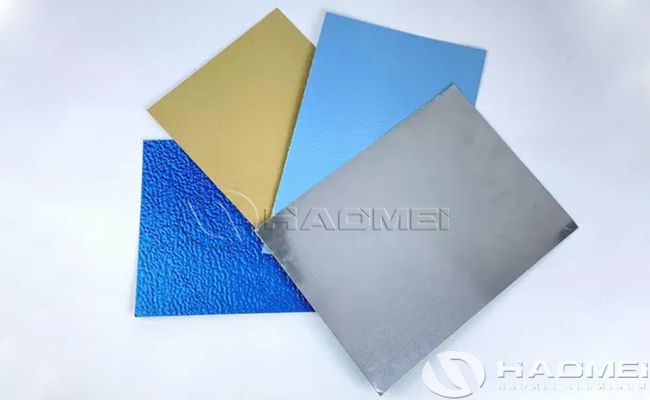

Our aluminum jacketing offer a wide range of surface treatments to meet your diverse needs:

- Smooth aluminum jacketing roll:

Reflects the inherently smooth, bright texture of aluminum, with a mirror-like surface and high reflectivity, effectively reflecting heat and providing excellent cooling. Furthermore, the glossy design is easy to clean and resists dust accumulation, making it widely used for insulating cold water pipes in hygiene-critical locations, such as food processing plants and pharmaceutical factories.

- Embossed aluminum jacketing roll:

A unique embossing process creates a unique pattern on the aluminum coil surface, reminiscent of the familiar orange peel texture. This embossing treatment not only increases the coil's surface area, improving its ability to dissipate and reflect heat, but also enhances its mechanical strength, making it more resistant to wear and impact. Embossed aluminum coils offer a unique decorative effect and can be used for chilled water pipe insulation projects in commercial buildings and office buildings, where aesthetics are crucial.

- Corrugated aluminum jacketing roll:

Their wavy structure imparts excellent mechanical properties. Compared to plain aluminum aluminum jacketing roll, corrugated aluminum aluminum jacketing roll are more rigid and can withstand greater impact. They are ideal for outdoor cold water pipes or industrial plants where pipe protection is critical and prone to accidental collisions. Furthermore, the air gaps between the corrugated sheets further enhance thermal insulation.

- Polysurlyn film and kraft paper laminated aluminum jacketing roll:

This composite product features a layer of poly-surlyn film and poly-kraft paper applied to the aluminum jacketing roll surface. The poly-surlyn film has excellent adhesion and adheres tightly to the aluminum roll, effectively isolating it from moisture, preventing rust and absorbing any moisture that may build up inside the pipe. The kraft paper provides a cushioning and protective surface, while also increasing friction, making it easier to wrap the pipe and preventing slippage. This type of laminated aluminum jacketing roll is often used for insulation of chilled water pipes in environments with extremely stringent requirements for moisture and corrosion resistance, such as buildings and chemical plants in coastal areas.

Features of chilled water pipe aluminium jacketing:

- High Corrosion Resistance:

Aluminum easily forms a dense aluminum oxide film in the air, which resists common acid and alkali corrosion. This effectively prevents rust and corrosion of cold water pipes due to environmental factors, extending the service life of the pipes.

- Lightweight:

Aluminum has a density of approximately 2.71 kg/cubic meter. Compared to metals like iron and stainless steel, the weight per square meter of aluminum sheet is less than one-third of that of stainless steel, reducing the pressure on the support and facilitating transportation and installation.

- Excellent Formability:

Highly malleable, it is easily processed and formed through bending, stamping, and stretching, making it easy to wrap around cold water pipes of various shapes and sizes.

- Decorative Effect:

Some chilled water pipe insulation aluminum jacketing roll feature a surface pattern such as orange peel, which not only provides insulation and protection but also adds a beautiful decorative effect to the piping system, enhancing the overall quality of the environment.

- Energy-saving and environmentally friendly:

Its excellent light and heat reflection properties reduce the transfer of external heat to cold water pipes, minimizing cooling losses during cold water transportation, thereby achieving energy-saving and environmentally friendly benefits.

Applications of chilled water pipe aluminium jacketing:

- Construction Industry: Used in central air conditioning systems and cooling pipes in buildings.

- Industrial Industry: Used in refrigeration equipment, cold storage, and cooling systems.

- Transportation: Maintaining stable temperatures during transportation in cold chain logistics.

live:onlinehcx