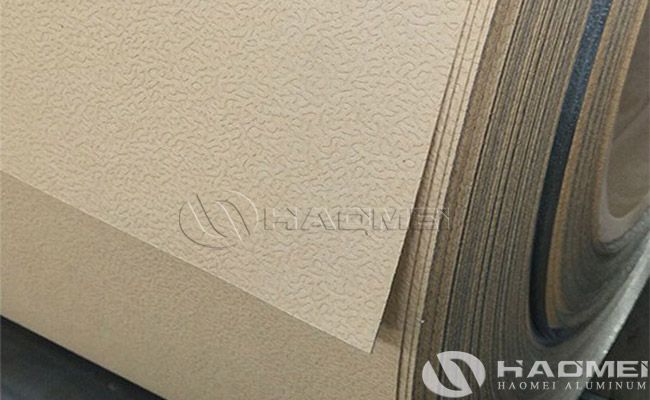

Aluminum stucco embossed with polykraft moisture barrier is a composite material that combines moisture-proofing, corrosion-proofing and decorative features. This kind of product made by hot-pressing polykraft paper and aluminum coil, then stucco embossing, and is widely used in pipe insulation, building waterproofing, and industrial corrosion protection.

Structure of Aluminum Stucco Embossed With Polykraft Moisture Barrier:

- Aluminum coil base material:

Commonly used materials are 1060 pure aluminum (80%) or 3003 aluminum-manganese alloy. 1060 pure aluminum is low-cost and easy to process, making it suitable for general moisture-proofing applications. 3003 alloy contains manganese, providing enhanced corrosion resistance and is commonly used in highly corrosive environments such as chemical and desulfurization processes.

- Moisture barrier polykraft paper:

Made from imported yellow kraft paper (approximately 80-120g), it undergoes special treatment to enhance tear resistance and moisture resistance. Some high-end products use FSC-certified 100% wood pulp kraft paper, meeting environmental and food contact standards.

Process of Aluminum Stucco Embossed With Polykraft Paper Moisture Barrier:

Aluminum Coil Pretreatment (Degreasing and Flattening) → Hot Pressing and Laminating with Kraft Paper → Embossing → Slitting → Packaging.

- Lamination Process:

High-temperature hot pressing (approximately 140°C) is used to tightly bond the kraft paper to the aluminum jacketing roll, eliminating the need for glue. The adhesive remains intact even after immersion in water for 24 hours, resulting in significantly stronger bonding strength than conventional glue.

- Embossing Process

Pattern Type: Primarily orange peel texture, the embossing depth is controlled between 0.1-0.15mm. For example, a 0.5mm thick aluminum coil increases to 0.6-0.65mm after embossing. Embossing not only enhances the surface aesthetics but also strengthens the material's mechanical strength and anti-slip properties.

Equipment and Precision: High-strength steel forged embossing rollers (550mm diameter, 1600mm width) are used to ensure a uniform, three-dimensional pattern, resulting in highly consistent patterns across the entire roll.

Applications of Aluminum Jacketing With Polykraft Moisture Barrier:

- Pipeline Insulation:

External protection for oil and gas pipelines in the Middle East and Southeast Asia, extending pipeline service life by over 10 years.

- Chemical Equipment:

Anti-corrosion coatings for desulfurization towers, reactors, and other equipment to protect against corrosion from acids, alkalis, and other chemicals. Construction Projects

- Exterior walls and roofs:

Replace traditional waterproofing membranes, combining embossed patterns for integrated decorative and protective applications.

- Ventilation ducts:

Provide moisture-proof and noise reduction in air conditioning systems, particularly suitable for high-humidity environments (such as basements and swimming pools).

Aluminum stucco embossed with polykraft moisture barrier, with their excellent overall performance and high cost-effectiveness, have become a preferred choice for moisture-proofing and corrosion-resistant materials in the industrial and construction sectors. With continued growth in market demand, they hold broad application prospects, particularly in infrastructure construction in countries along the Belt and Road Initiative.

live:onlinehcx