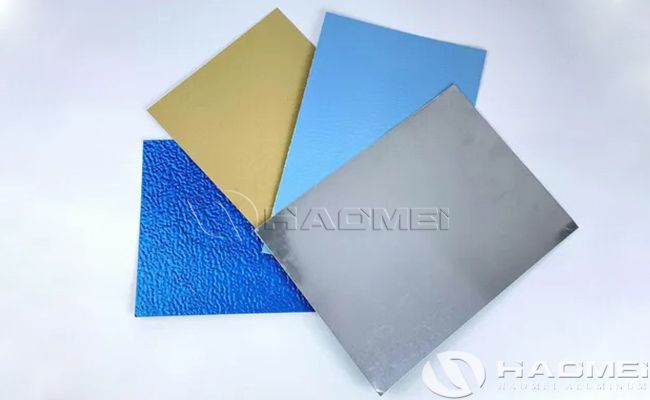

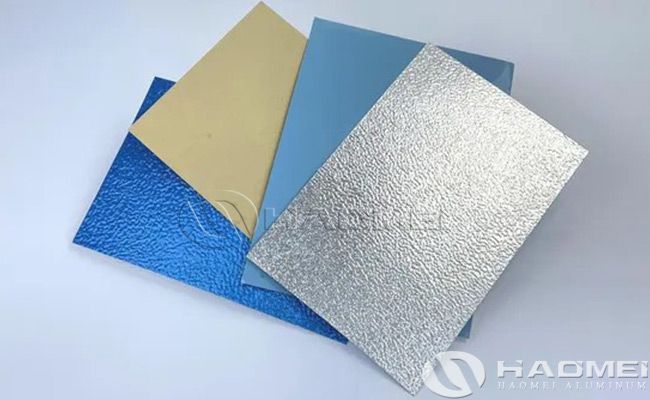

Aluminum roll jacketing with polyfilm moisture barrier is a functional material that utilizes a composite process to bond a specific moisture-proof film (polysurlyn film or polykraft paper) to the surface of an aluminum coil base. It combines the thermal insulation and protective properties of the aluminum roll jacketing with the moisture-proof capabilities of the film. It is widely used in construction, industrial piping, equipment packaging and other fields. Its core function is to create a dual "insulation + moisture-proof" barrier for the protected object, extending its service life and ensuring stable performance.

Aluminum Coil Base (Core Support and Insulation Layer)

As the base carrier, aluminum coil primarily provides thermal insulation, structural strength, and corrosion resistance. Commonly used materials fall into three categories:

1. Series 1xxx Pure Aluminum Coil (such as 1060 and 1050):

High purity (≥99.5%), good ductility, and low cost, with stable thermal insulation performance. It is suitable for general applications such as municipal piping and roof/wall insulation of residential buildings, where high strength requirements are not critical.

2. Series 3xxx aluminum-manganese alloy coils (such as 3003):

The addition of manganese increases hardness and fatigue resistance, resulting in superior weather resistance compared to pure aluminum. They are suitable for use as protective layers for outer packaging (e.g., equipment casing insulation and outdoor pipe protection), offering protection against minor impacts and exposure to wind and sun.

3. Series 5xxx aluminum-magnesium alloy coils (e.g., 5005):

Containing magnesium, they offer excellent rust resistance while maintaining a certain level of strength. They are suitable for use in humid, highly corrosive environments such as those found in maritime, chemical, and coastal areas (e.g., chemical plant pipelines and ship equipment insulation).

Moisture-proof film layer (core moisture barrier):

Common options include Polysurlyn and polykraft paper.

1. Polysurlyn Material:

A multilayer composite film of polyethylene (PE) and surlyn polymer (ionomer resin).

- Thickness:

Thin (typically 7-15μm) for lightweight.

- Moisture-proof:

Excellent airtightness, capable of isolating liquid water and water vapor, and resistant to high and low temperatures (-40°C to 80°C).

- Weatherproof:

Strong UV and aging resistance, resists cracking and delamination even with long-term outdoor use.

- Adhesion stability:

After lamination under high temperature and high pressure, it adheres tightly to the aluminum coil and resists peeling.

- Applications:

Outdoor environments with high humidity and large temperature fluctuations (such as outdoor pipelines and cold storage insulation).

2. Polykraft paper (usually reinforced composite type).

High-strength paper made from plant fibers, some are laminated with PE film for enhanced waterproofness.

- Thickness:

Thicker (typically 50-100μm) for a more solid feel.

- Moisture-proof:

Basic moisture-proof, laminated with PE. Waterproofing can be improved, but prolonged immersion can easily absorb moisture.

- Weather resistance:

Weak. Susceptible to moisture, mildew, and embrittlement when exposed outdoors, requiring a protective layer.

- Adhesion stability:

Requires lamination with an environmentally friendly adhesive. Pay attention to bond strength in humid environments.

- Applications:

Indoor, dry environments (such as indoor wall insulation, equipment packaging), and temporary protection.

Performance and Characteristics of Aluminum Roll Jacketing With PFMB:

- Thermal insulation:

The aluminum coil itself offers excellent thermal insulation properties, effectively reducing the temperature difference between indoors and outdoors and lowering energy consumption.

- Moisture and corrosion resistance:

The laminated poly film offers excellent airtightness and waterproofing, preventing moisture intrusion. The aluminum coil also exhibits excellent corrosion resistance. This combination effectively prevents mold and decay in the insulation, extending its service life.

- Strong weather resistance:

Polymer films like PolySurlyn film offer excellent weather resistance and durability, maintaining excellent adhesion and strength even under harsh conditions such as heat aging, hot and cold water, and low temperatures.

- Excellent Processability:

Aluminum jacketing rolls can be cut, bent, and formed as needed to meet the needs of various applications.

Applications of aluminum roll jacketing with polyfilm moisture barrier:

- Construction:

Used for wall insulation, roof insulation, and floor insulation, it improves building energy efficiency, achieves energy conservation and emission reduction goals, and protects buildings from moisture.

- Industrial Pipelines:

Widely used for pipe insulation in refineries, power plants, and chemical plants, it effectively resists corrosive environments, maintains a stable temperature for the media within the pipes, and ensures normal operation.

-Electrical Equipment:

Suitable for cable protection and electrical packaging, it isolates external electromagnetic interference and electrostatic interference, while also providing moisture and corrosion protection, protecting electrical equipment and extending its service life.

live:onlinehcx