Aluminium corrugated with polykraft paper back for moisture barrier is a composite material that combines aluminum sheet, kraft paper and a corrugated structure. It combines moisture-proofing, thermal insulation, and structural reinforcement properties, making it widely used in industrial insulation, cold chain logistics, architectural decoration and other fields.

Product Features of Aluminium Corrugated with PolyKraft Paper Moisture Barrier

- Outstanding Moisture-Proof Performance

The kraft paper backing layer effectively blocks moisture penetration through its physical barrier, making it particularly suitable for humid environments (such as chemical pipeline insulation and cold storage construction). The polykraft paper's fiber structure absorbs trace moisture, delaying surface corrosion and extending the service life of the aluminum sheet.

- Corrugated Structure Enhances Performance

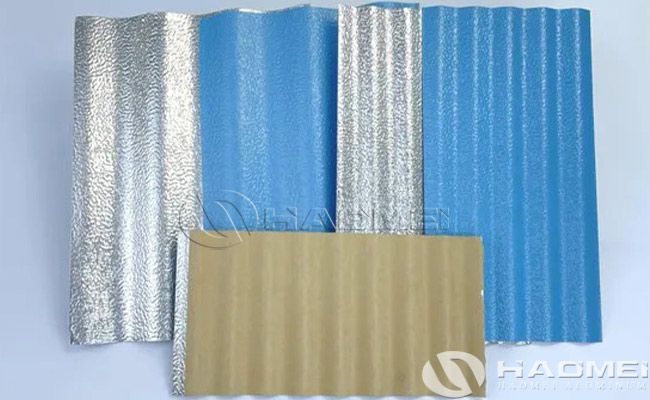

The aluminum sheet surface is pressed into a corrugated pattern (such as Type 750, Type 840, and Type 900). The three-dimensional texture increases surface friction and reduces the risk of slippage during installation. The corrugated design also enhances sheet rigidity, reducing deformation during transportation and construction.

- Optimized Lamination Process

Hot Lamination: The kraft paper is bonded to the aluminum sheet through high-temperature melting, resulting in a high bond strength, but the temperature must be controlled to prevent oxidation of the aluminum sheet. Aluminum sheet with polykraft moisture barrier has been experimentally verified to maintain bond integrity even after immersion in water for 24 hours. This process not only enhances moisture resistance but also avoids the temperature-sensitive nature of traditional adhesive bonding.

- Flexible Material Selection

1060 Alloy: Pure aluminum, low-cost, suitable for general industrial insulation.

3003 Alloy: An aluminum-manganese alloy with strong rust resistance, suitable for corrosive environments such as chemical processing.

- Quality Acceptance Criteria

Appearance: The kraft paper backing must be free of damage and bubbles, and the aluminum sheet surface must have clear embossed patterns.

Performance: According to GB/T3880-2012 testing, tensile strength must be ≥110 MPa and elongation must be ≥8%.

Environmental: The kraft paper must be FSC-certified, and the adhesive must contain a volatile organic compound (VOC) content of ≤50 g/L.

Application Scenarios of Aluminium Corrugated Sheet with PolyKraft Paper

- Pipeline Insulation Projects

For steam pipeline outsourcing in power plants and chemical plants, corrugated aluminum sheet with kraft paper backing can replace traditional rock wool and aluminum cladding, achieving both insulation and protection in a single layer. For example, 750 aluminum sheeting (35mm corrugated height, 125mm corrugated spacing) is commonly used for power plant pipeline insulation, improving installation efficiency by over 30%.

- Cold Chain Logistics Facilities

This type of sheeting is used on cold storage walls and ceilings. The kraft paper backing prevents condensation from penetrating the insulation layer, thus reducing energy consumption due to increased humidity. Test data shows that this reduces daily electricity consumption in cold storage by 8%-12%.

- Architectural Decoration

Corrugated aluminum sheet with poly kraft paper backing can serve as a decorative surface for interior partitions while also meeting fire safety regulations thanks to the flame-retardant properties of kraft paper. Some projects utilize a 0.5mm thick aluminum sheet + kraft paper composite structure, which is 15% lighter per unit area than pure aluminum sheeting, thus reducing building loads.

Corrugated aluminum sheet with polykraft paper backing moisture barrier has become an ideal material in the construction and industrial fields due to its excellent moisture resistance, high strength and ease of construction.

live:onlinehcx