As the manager of Haomei Aluminum's export business, with years of experience in the field of aluminum jacketing rolls, I am well aware of the stringent requirements of overseas markets regarding product adaptability, durability, and manufacturing precision. Below, I will provide a structured and detailed explanation of 5 different types of aluminum jacketing, combining industry application scenarios and core parameters. All products comply with GB/T 3880-2012 standards, with an aluminum content of ≥99.6% in the core material, balancing performance and cost optimization to meet the needs of various overseas scenarios.

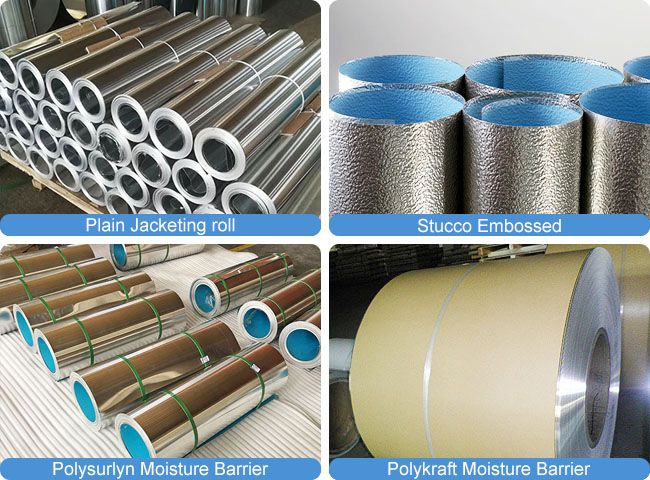

1. Flat/Plain Aluminum Jacketing

Flat aluminum jacketing rolls are an essential basic model in the industrial insulation field, emphasizing high cost-effectiveness and versatility for all scenarios. Using 1060 pure aluminum or 3003 aluminum-manganese alloy as the base material, the thickness tolerance is strictly controlled within ±0.02mm, with a density of only 2.71g/cm³, weighing less than 1/3 of stainless steel, significantly reducing construction, handling, and cross-border transportation costs. The surface undergoes anodizing treatment, forming a dense protective oxide film that withstands salt spray corrosion for over 800 hours. It is suitable for common applications such as municipal pipelines, HVAC systems, and general factory insulation. Its heat loss rate is 50% lower than traditional sheet metal materials, making it a fundamental choice that balances cost-effectiveness and practicality.

2. Stucco Embossed Aluminum Jacketing

Embossed aluminum jacketing rolls feature an orange peel texture as their core product, offering both protective and decorative attributes in addition to insulation. The pattern is formed through precision rolling, resulting in uniform texture and a delicate feel. Thickness options range from 0.3-1.2mm, with a stable thickness increase of approximately 0.2mm after rolling, ensuring controllable dimensional accuracy. Besides its core insulation function, its unique texture enhances adhesion to the insulation layer, effectively preventing issues like hollow areas and detachment after construction. It also improves surface scratch and wear resistance, making it widely used in building exteriors, equipment tanks, high-end factories, and other scenarios where aesthetics are important. It is suitable for mid-to-high-end overseas projects.

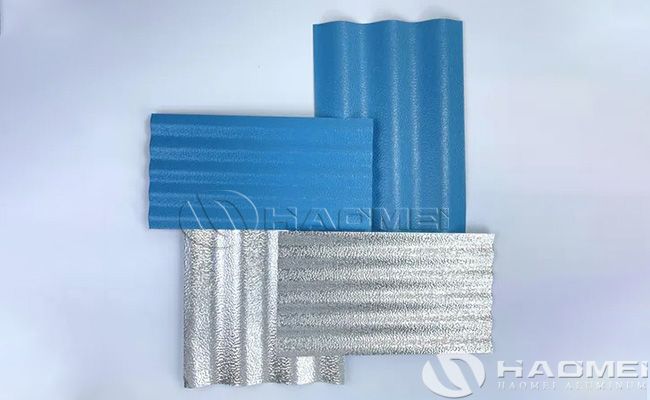

3. Corrugated Aluminum Jacketing

Corrugated aluminum jacketing rolls are specifically designed for large-scale industrial applications, offering five mainstream corrugation types (A, B, C, etc.) to precisely adapt to heavy-duty insulation scenarios such as oil refineries, power plant pipelines, large-span building roofs, and large storage tanks. Leveraging the advantages of 3003 aluminum-manganese alloy substrate, the product's tensile strength is 30% higher than ordinary pure aluminum jacketing rolls, capable of withstanding high and low temperature cycling environments from -40℃ to 120℃, with a service life exceeding 15 years. The corrugated structure inherently provides load-bearing and seismic resistance, eliminating the need for additional reinforcement during construction. Efficiency is 40% higher than flat aluminum jacketing rolls, and the aluminum recycling rate exceeds 80%, meeting the stringent requirements of industrial applications while aligning with overseas environmental policy trends.

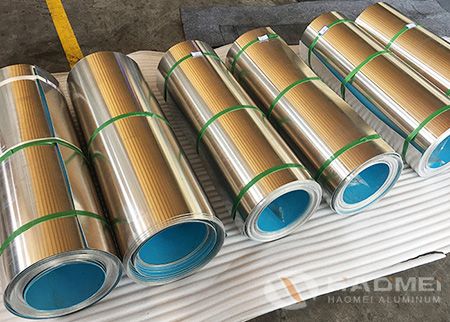

4. Aluminum Jacketing with Kraft Paper

Kraft paper coated aluminum jacketing rolls are designed for low-to-medium humidity environments. They utilize 10-15 micron thick kraft paper, processed with a 140℃ high-temperature hot-pressing composite process, resulting in high adhesion and no delamination or peeling even after 24 hours of immersion in water. The accompanying kraft paper weighs only 0.08 kg per square meter, enhancing moisture protection without significantly increasing overall weight or cost. Suitable for building insulation in low-to-medium humidity areas, short-distance cross-border transportation protection, and moisture-proof wrapping of general equipment, its market demand has steadily increased in recent years in humid and hot regions such as Southeast Asia and South America, making it a high-performance, cost-effective moisture-proof solution.

5. Aluminum Jacketing with Poly Surlyn

Poly surlyn film-coated aluminum jacketing rolls are developed for extreme environments with high corrosion and high humidity. The accompanying polysurlyn film is 0.076mm thick and employs a triple-protection structure of "aluminum roll + adhesive layer + polysurlyn film," effectively blocking moisture, acid and alkali media, and chemical corrosion. After hot-pressing lamination, the film layer exhibits extremely high peel strength to the aluminum jackating roll, with no detachment even when torn by hand. It demonstrates excellent weather resistance and corrosion resistance, performing exceptionally well in harsh environments such as the high temperature and humidity of the Middle East, coastal salt spray, chemical desulfurization, and marine facilities. The product supports subsequent deep processing such as embossing and cutting, with a warranty period of up to 10 years, providing long-term thermal insulation protection for overseas projects in extreme environments.

Haomei Aluminum is always guided by the specific needs of overseas scenarios. Its entire types of aluminum jacketing rolls undergoes strict quality control throughout the entire process, from substrate selection and processing to finished product testing. It offers full-thickness customization from 0.1-3.0mm, exclusive tile/pattern development, and rapid slitting services. We deeply understand the core demands of overseas projects for timely delivery and product stability. Leveraging our own modern production lines, we achieve rapid delivery of standard specifications within 3-5 days and delivery of specially customized products within 7-10 days. With precise parameter control, mature industry experience, and comprehensive services, we safeguard your overseas projects.

live:onlinehcx